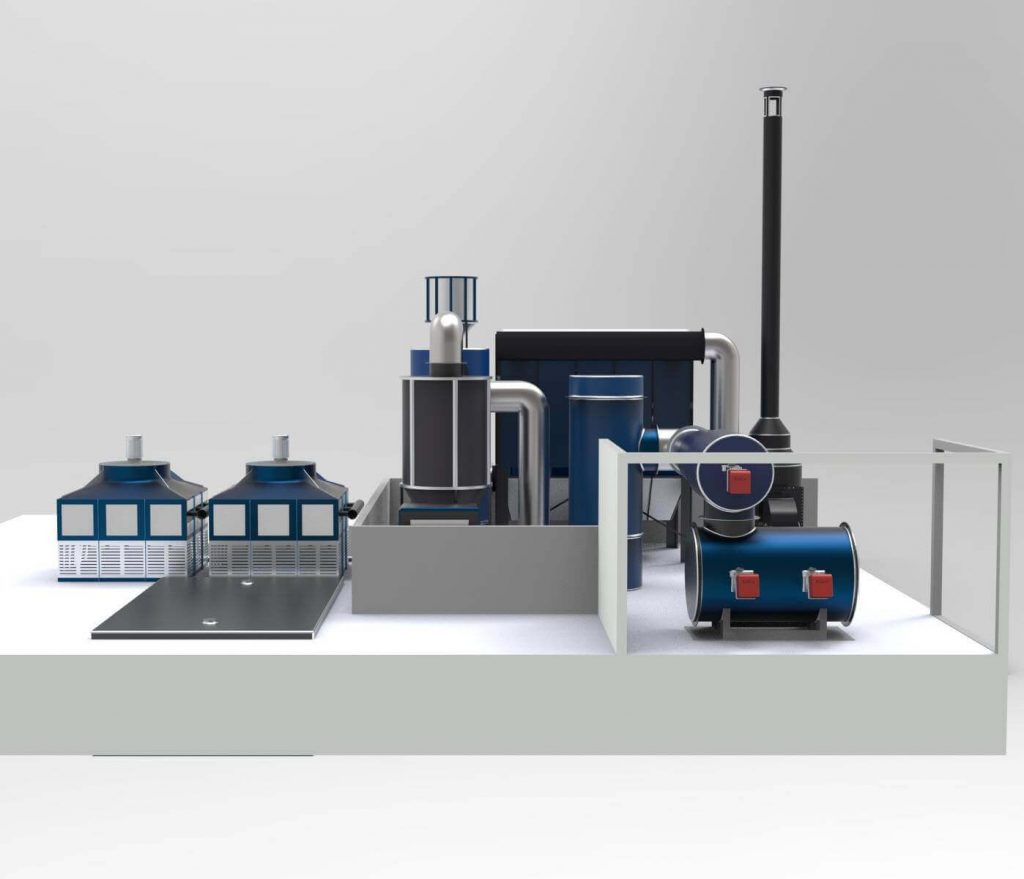

NOS INCINERATEUR

Les déchets d’activités de soins à risques infectieux (DASRI) sont les déchets issus des établissements actifs dans les domaines de la médecine humaine et vétérinaire. De par leur origine et leur nature, ces déchets peuvent causer des risques pour l’homme et d’autres organismes vivants et pour l’environnement (Provoque des maladies graves, La contamination des sources d’eau, et La pollution de l’air).

La gamme des incinérateurs de BIOWAS INCINERATORS est fabriquée à partir de matériaux de la plus haute qualité pour être plus efficaces, fiables et durable. Nos systèmes d’incinération ont une meilleure qualité et une longue durée de vie garantissant un bon retour sur investissement.

DECHETS HOSPITALIER

- les déchets anatomiques (tissus, organes ou fluides humains, parties du corps, fœtus, produits sanguins non utilisés…)

- Déchets radioactifs, verrerie, emballages ou papier absorbant contaminés, urines et excréments de patients traités ou testés avec des radionucléides non scellés, sources scellées.

LES DECHETS INFECTIEUX

- Les déchets infectieux (Seringues, aiguilles, lames bistouri, dispositifs à perfusion, le verre cassé …etc.)

- Bandages, écouvillons, compresses imprégnées du sang, flacons de vaccin, matériels contaminés …etc.

- les déchets cytotoxiques, produits chimiques génotoxiques.

DECHETS PHARMACEUTIQUE

- les produits pharmaceutiques expirés ou qui ne sont plus nécessaires, articles contaminés ou contenant des produits pharmaceutiques.

- Emballages papier, emballages plastique, déchets métalliques, déchets de verre …etc.

LES AVANTAGES

- Une combustion propre et complète ;

- Garantie de 12 mois ;

- Réduction des odeurs et des émissions ;

- Systèmes d’incinération robustes et durables ;

- Systèmes d’incinération efficaces thermiquement ;

- Consommation rentable de carburant

- Systèmes d’incinération résistants aux impacts,

- Disponibilité en multiples dimensions et design ;

- Elimination de toute contamination ;

- Consommation rentable de carburant

- Bon retour sur l’investissement

- Equipe d’ingénieur disponible pour l’échelle mondial.

- AUTRES OPTIONS POUR DES INCINERATEURS SURE MESURE:

- Option de système de chargement automatique.

- Option de système d’injection de déchets liquides spéciaux.

- Option de système d’élimination automatique des cendres.

- Option de récupération d’énergie disponible.

LES CARACTERISTIQUE

- La chambre de combustion primaire : 800 – 950 °C

- La chambre de post-combustion secondaire : 1100 – 1200 °C

- Temps de séjour : plus de 2 s

- Structure en acier (de 10 mm) résistante, et peinture anticorrosion.

- Béton et Briques réfractaires de haute qualité

- Isolation micro-poreuse de haut grade.

- Brûleurs à impulsions

- Unité de contrôle intelligent et automatique.

- Système de traitement de fumée intégré

- Différents types de carburent : gaz, gaz naturel, gazoil.

les détails de l’incinérateurs

| Type de Déchets | Médicaux |

| Chambre Primaire | 950 ° C |

| Chambre Secondaire | 1200 °C |

| Carburant | Diesel/Gaz |

| Fonctionnement | Automatique |